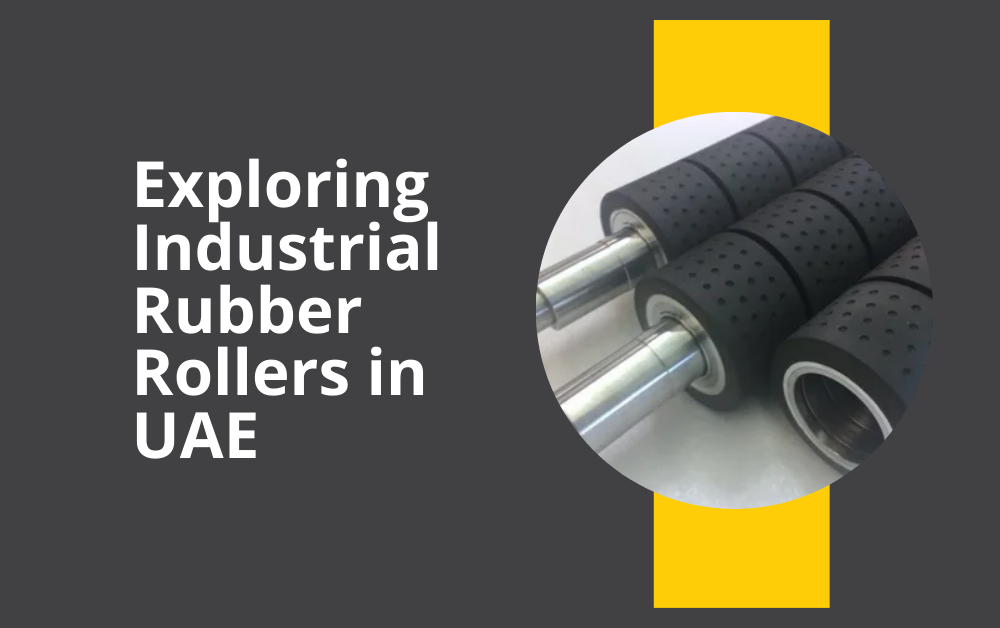

Rubber rollers are an integral part of various industrial applications in the UAE, from printing and packaging to textile manufacturing. This blog aims to provide a detailed guide about industrial rubber rollers in UAE, exploring their uses, benefits, types, and how to choose the right one for your business needs. We’ll break down everything in simple terms, making it easy for everyone to understand.

What Are Industrial Rubber Rollers?

Industrial rubber rollers are cylindrical tools or components covered with rubber, designed to facilitate movement or processing of materials in industrial settings. They are widely used because rubber is flexible, durable, and can be customized for different functions.

Common Uses of Rubber Rollers

Rubber rollers are versatile and are used in various industries. Some common uses include:

- Printing: They help transfer ink uniformly.

- Textile: They process fabrics without causing damage.

- Packaging: They assist in moving and sealing packaging materials.

Benefits of Using Industrial Rubber Rollers

Durability and Resistance

Rubber rollers are built to last. They can withstand heavy usage and are resistant to chemicals and temperature changes, making them ideal for harsh industrial environments.

Flexibility and Customization

One of the best features of rubber rollers is their flexibility. They can be custom-made to meet specific industrial needs, varying in hardness, size, and rubber type.

Improved Processing Quality

Using the right type of rubber roller ensures that materials are processed smoothly, enhancing the quality of the final product. This is crucial in industries like printing, where precision is key.

Types of Rubber Rollers Used in the UAE

Nitrile Rubber Rollers

Perfect for use in oil handling industries because of their oil-resistant properties.

Silicone Rubber Rollers

These are excellent for high-temperature applications, commonly used in heat setting processes.

Neoprene Rubber Rollers

Known for their durability, neoprene rollers are used in applications involving weathering and ozone resistance.

How to Choose the Right Rubber Roller for Your Industry

Choosing the right rubber roller requires understanding your industry’s specific needs. Here are some tips to help you select the appropriate roller:

Assess the Application Needs

Consider the environment in which the roller will be used. Factors like temperature, exposure to chemicals, and the type of material being processed are crucial.

Understand the Different Types of Rubber

Each type of rubber offers different benefits. For instance, silicone is best for high temperatures, while nitrile is ideal for oil resistance.

Consult with a Specialist

It’s always a good idea to talk to a specialist who can provide insights based on experience in the field. They can offer tailored advice that fits your particular industrial needs.

Maintenance Tips for Industrial Rubber Rollers

Regular Cleaning

Keep the rollers clean to ensure their longevity. Dirt and debris can cause wear and tear over time.

Routine Inspection

Regularly inspect the rollers for any signs of damage or wear. Early detection can prevent costly repairs later.

Proper Storage

When not in use, store the rollers properly to avoid deformation. Keep them in a cool, dry place away from direct sunlight.

Where to Find Quality Industrial Rubber Rollers in UAE

Local Manufacturers

UAE hosts several quality manufacturers of industrial rubber rollers. These local options can provide quick supply and support.

International Suppliers

If local varieties do not meet your specific needs, international suppliers might have what you need, though consider shipping times and costs.

Online Industrial Marketplaces

Online platforms can be a good resource for comparing different products and prices at once. They often have detailed product specifications and reviews from other users.

Conclusion

Understanding and selecting the right industrial rubber roller for your business in the UAE can significantly affect your operational efficiency and product quality. By considering the types of rollers, their benefits, and maintenance needs, you can make an informed decision that ensures long-term benefits for your industrial processes.

Whether you’re in printing, textile, or packaging, the right rubber roller can make a big difference. Always consider your specific needs and consult with experts to ensure you choose the best option available. With the right knowledge and tools, your industry can operate smoothly and more efficiently.

For more insightful articles related to this topic, feel free to visit integratedblogs